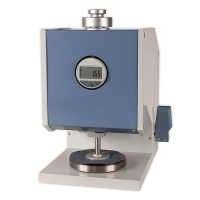

Coating thickness gauge MiniTest 650 Elektrophysik Vietnam

Price: Contact

Brand: Elektrophysik Vietnam

Category: Thiết bị đo lường & Kiểm tra

Supplier: ansvietnam

Origin: Germany

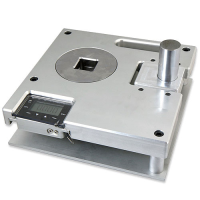

Coating thickness gauge MiniTest 650 Elektrophysik Vietnam

The MiniTest 650 is robust and perfectly suited to coating thickness measurement in harsh conditions and on abrasive surfaces such as:

- Sandblasted steel

- Heavy duty corrosion protection in ship building

- Offshore installations and mining facilities

- Plasma-sprayed surfaces

MiniTest 650 – The Robust coating thickness measurement gauge

The MiniTest 650 has a fixed external probe for all non-magnetic coatings on steel and all insulating coatings on nonferrous metals. For measurement on rough steel surfaces, e.g. in shipyards, the F probe comes equipped with special wear protection to ensure long service.

MiniTest 650 F

To measure non-magnetic coatings (varnishes, enamels, chromium etc.) on ferromagnetic substrates (e.g. steel used in construction and for auto body).

With statistics display (number of readings taken, mean values, standard deviation, maximum, minimum).

Measuring range 0 to 3 mm.

Interchangeable measuring units µm or mils.

Enables 1-point and 2-point calibrations.

MiniTest 650 N

To measure insulating coatings (varnishes, enamels, anodic coatings etc.) on non-ferrous metals (aluminium, copper, brass etc.).

With statistics display (number of readings taken, mean values, standard deviation, maximum, minimum).

Measuring range 0 to 2 mm.

Interchangeable measuring units µm or mils.

Enables 1-point and 2-point calibrations.

MiniTest 650 FN

To measure non-magnetic coatings (varnishes, enamels etc.) on ferromagnetic substrates (e.g. steel used in construction and for auto body) and to measure insulating coatings (varnishes, enamels, anodic coatings etc.) on non-ferrous metals (aluminium, copper, brass etc.).

With statistics display (number of readings taken, mean values, standard deviation, maximum, minimum).

Measuring range 0 to 2 mm.

Interchangeable measuring units µm or mils.

Enables 1-point and 2-point calibrations.