Contour check shape CC SHAPE 50 LAP laser Vietnam

Price: Contact

Brand: Lap Laser VietNam

Category: Meter

Supplier: ansvietnam

Origin: Germany

Contour check shape CC SHAPE 50 LAP laser Vietnam

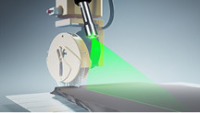

The pioneering measuring system for optical contour measurement and surface defect detection on long products of your steel profile

CONTOUR CHECK SHAPE has proven itself in hot rolling of long products and is an essential part of the rolling process in many factories. It checks hot and cold steel profiles with the help of three-dimensional surface reconstruction. It records dimensional errors due to rolling defects and surface defects such as rolling seams from calibre overfill, grooves, fire crack marks, rolling marks, and more.

The innovation lies in the optimized laser light section sensors, which LAP constructs with its own laser technique and high-end industry cameras. Four cameras observe the cross section continuously. The object to be measured is scanned lengthwise at a rate of up to 2000 Hz. The camera with high-speed image recording captures the laser line while the often still glowing steel enters the measuring field.

Regardless of the profile form (round, square, ...), the CONTOUR CHECK SHAPE supports your production process and verifiably reduces scrap. One additional feature is the precise measurement of rebar whereby measuring values like the contour of the core, the rib height and the weight per meter are accurately calculated.